Tech

Beyond Speed: 5 Ways 5-Axis CNC Machining Solves Design Challenges and Cuts Costs

Introduction

Have you ever had to simplify an innovative part design because it was too complex or costly to machine with traditional 3-axis mills? You’re not alone. Innovation is being taken to extremes across industries, such as aerospace and medical equipment, to robotics and automotive. The components are being made lighter, stronger and more integrated than ever. However, these developments tend to present geometrical challenges that traditional machining just cannot effectively work with effectively.

That is where 5-axis CNC machining comes in. Much more than just speed, it is a jump up in capability, flexibility and cost-efficiency. The technology will enable manufacturers such as LS Manufacturing to make complex CNC parts with a high level of precision and also make them in less time and at a low cost of production.

Precision manufacturing trends 2024

Figure 1: The 4 key trends shaping precision manufacturing in 2024, driven by the need for complexity, speed, and efficiency.

Demystifying 5-Axis CNC Machining

We will begin by taking a look at the fundamentals of 5-axis CNC machining in order to appreciate its power. The standard 3 axis machines move cutting tools in three linear motions 2 X, 2 Y, and 2 Z. Conversely, a 5-axis CNC machine includes two additional rotational axes (usually A and B) which enables the cutting tool to access the workpiece in virtually any direction.

Imagine a sculptor that can walk around a sculpture and carve it in any angle without ever having to move it. This mobility ensures that there is no need to have many arrangements and that there is uniformity in the accuracy on complex surfaces.

(Visual Aid Suggestion) Add a diagram with 5-axis CNC machine movements. Image Description: (CNC machine movement diagram in 5 axis.)

The Three Core Strategic Advantages of 5-Axis Machining

Advantage 1: Unmatched Geometric Capability and Superior Accuracy

Where handling the complex objects like turbines blades, orthopedic implants, or complex housings, accuracy matters a lot. Under 5-axis machining, there can be several sides to the part being worked on during one set up and this significantly minimizes the amount of errors that arise due to hand-setting parts.

In LS Manufacturing, we are currently utilizing 5-axis technology to machine complicated orthopedic implant surfaces to the medical industry in just one machine operation. This is done to realize that critical biomechanical tolerances are obtained with micron level accuracy- almost impossible with 3-axis systems. The outcome is more precision, high quality parts and less chance of dimensional deviation.

Advantage 2: Dramatically Reduced Production Steps and Lead Time

Conventional machining may need several orientations, individual jigs and a human hand to access all sides of a complex component. Each stage is time-consuming, expensive and misaligning.

On the contrary, 5-axis machining simplifies the whole procedure. The machine is also able to accomplish a complete component in a single smooth process with simultaneous movement on various axes.

Reducing setups translates directly into shorter project lead times and faster time-to-market. For instance, in a recent project at LS Manufacturing, a part that previously required three separate setups and five days of machine time was completed in just one setup and two days using our 5-axis CNC machining services. This kind of efficiency is transformative for both prototyping and production environments.

Advantage 3: Enhanced Surface Finish and Lower Total Cost of Ownership (TCO)

The advantage of a high-quality surface finish is one of the few that have been ignored on 5-axis machining. Since the cutting tool remains on the optimal orientation in the process, it provides a uniform cutting environment and minimizes the wear as well as chatter of the tool. The result? A more polished or refined surface finish which frequently obviates secondary or hand polishing or finishing.

This has a direct effect on the total cost of ownership (TCO) in terms of business. Although the hourly rate of a 5-axis machine can be increased, it can save a lot of fixtures, manpower, and scrap, which can make the total cost of the project lower. The increased dimensional accuracy and finish also reduce rework and guarantees that the components last longer.

Case Study: Aerospace Lightweighting Project

The Challenge: A Complex, Lightweight UAV Component

One of the major manufacturers of drones addressed LS Manufacturing with a difficult request: it needed a lightweight yet strong aluminum alloy wing root fitting. The component needed complicated internal pathways and organically shaped forms to reduce weight to the minimum.

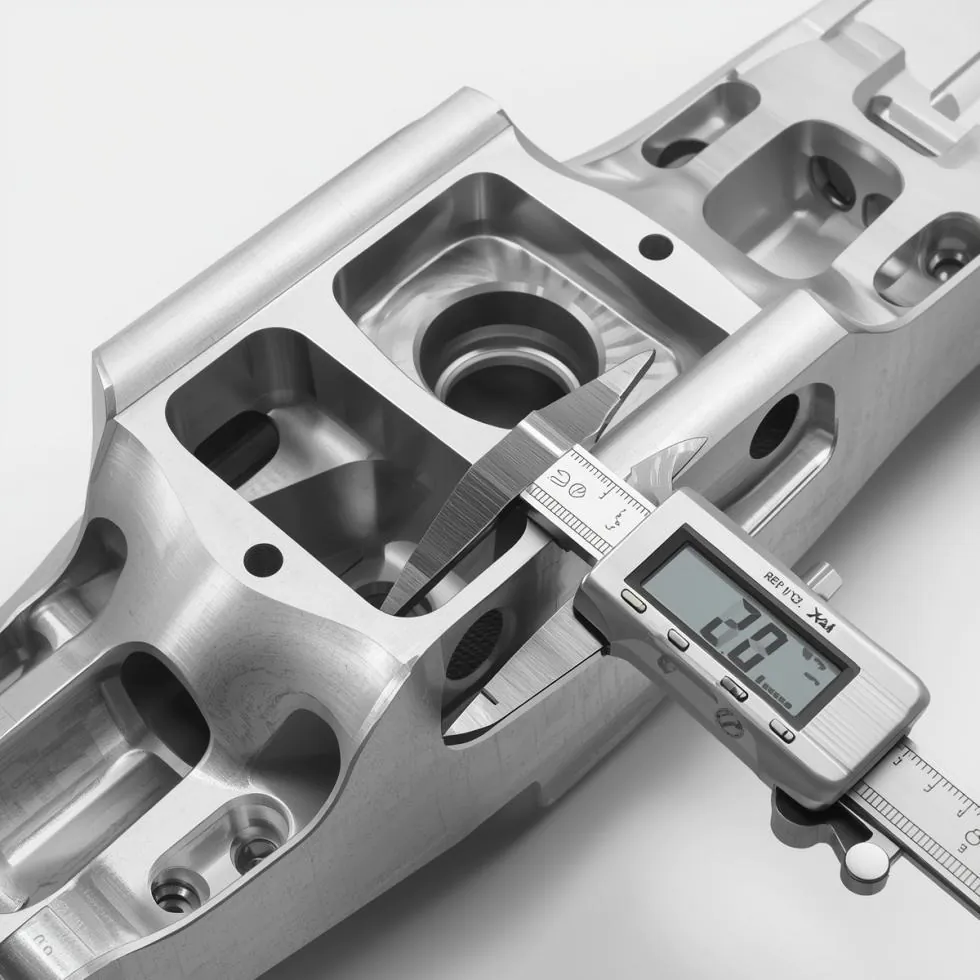

5 axis machined aerospace uav component

The 3-axis machining that was in use failed in this. It was not able to reach inside features with effectiveness, which led to the unproductive material removal, a lot of manual intervention, and high scrap rate. Project schedules were being jeopardized and the cost of production was increasing. This project is a prime example of how 5-axis technology is essential for producing complex CNC parts that meet extreme performance criteria.

Figure 2: This complex, lightweight aluminum part fitting for a UAV was machined to precise tolerances in a single setup on our 5-axis CNC centers.

The LS Manufacturing Solution

To tackle this challenge, the engineering team at LS Manufacturing first conducted a thorough Design for Manufacturability (DFM) analysis. This collaborative process led to a minor but critical design suggestion to reinforce a thin-wall section, enhancing rigidity for machining and overall part performance. Leveraging our expertise in high-precision 5-axis CNC machining, we then employed simultaneous 5-axis toolpaths to manufacture these complex CNC parts with unmatched accuracy. This strategy allowed for the accurate machining of both internal and external geometries in a single clamping, optimizing tool engagement angles and mitigating vibration to handle the delicate thin walls effectively.

Our expertise in high-precision 5-axis CNC machining was instrumental in developing a robust and efficient process plan. Get an Instant Quote Now!

-

Resources4 years ago

Resources4 years agoWhy Companies Must Adopt Digital Documents

-

Resources3 years ago

Resources3 years agoA Guide to Pickleball: The Latest, Greatest Sport You Might Not Know, But Should!

-

Resources8 months ago

Resources8 months ago50 Best AI Free Tools in 2025 (Tried & Tested)

-

Guides2 years ago

Guides2 years agoGuest Posts: Everything You Should Know About Publishing It