Tech

CNC Machining Tolerances: A Practical Guide for Designers to Reduce Cost and Time

The Importance of Tolerances in CNC Machining

With precision manufacturing, CNC machining tolerances are used to determine the precision with which a part should match its intended size and shape. Such tiny numerical figures can spell the difference between an assembly that fits like a glove, functions with ease, or one that cannot even start at all.

However, the right balance, avoiding precision to the point that cost increases or production gets delayed is one of the biggest challenges that designers face. This article discusses the impacts of tolerances on cost, lead time, and manufacturability and how their strategic application can dramatically enhance your project results.

Understanding the Basics of Machining Tolerances

Tolerance A tolerance is the permissible distance that may exist around a given dimension usually expressed as a plus-or-minus (±) amount. To say the least, given a hole with a design of 10.00 mm +0.05 mm, it can be between 9.95 mm and 10.05 mm.

Most general-purpose parts do not require higher machining tolerances than those found in such standard machining tolerances such as ISO 2768-mK. They are a great combination of functionality and affordability.

Nonetheless, when performance is directly influenced by tight tolerance machining is required. Other industries like aerospace, medical and robotics frequently need tolerances as small as +/-0.005 mm to make parts fit and work exactly. Although possible, these tolerances require increased amounts of time, cost and specialized equipment – all of which any designer should take into consideration before committing to paper.

How Tolerances Influence Cost and Lead Time

Tighter tolerances deliver greater precision — but that precision comes at a price.

- Increased Machining Cost

- Longer cutting cycles: Achieving extreme accuracy requires slower feed rates and smaller tool passes.

- Advanced equipment: High-precision jobs often rely on specialized 5-axis CNC machines or wire EDMs.

- Detailed inspections: Tight tolerances demand additional quality checks using CMMs and optical measurement systems.

- Higher rejection rates: Even minor deviations can result in scrapped parts, increasing material and labor costs.

Figure 2: The exponential relationship between tolerance tightness and cost/lead time. As shown, pursuing extremely tight tolerances leads to an exponential increase in cost and production time.

- Extended Production Time

Accuracy has its price in complexity of process. Other preparation, inspection, and possible rework add to manufacturing time. The narrower the tolerance, the more time it will take to complete each part.

Knowing the impact of tolerances on cost and time, the designer can make a knowledgeable choice in manufacturing that maximizes cost and time.

Design Tips for Optimizing Tolerances

Design efficiency begins with intelligent tolerance planning. The key is knowing where to apply precision — and where to relax it.

Golden Rule: Apply tight tolerances only to critical features that affect functionality, fit, or performance.

Tip 1: Define tolerances by function.

Avoid over-specifying dimensions. Only assign strict tolerances to features that directly impact how the part interacts with other components.

Tip 2: Consider tool access and manufacturability.

Parts with deep cavities, thin walls, or complex shapes are harder to machine within tight limits. Slightly relaxing tolerances in these areas can lead to faster production and lower costs.

Tip 3: Collaborate early for manufacturability feedback.

Working closely with your CNC partner early in the design phase can help identify unnecessary constraints.

At JS Precision, we provide DFM (Design for Manufacturability) feedback to help clients pinpoint overly tight tolerances before machining begins. This proactive approach often reduces production costs by up to 20% while improving lead times.

Case Study: How Smart Tolerance Adjustments Saved a Project

A client approached JS Precision with an aluminum component design that required tight tolerances — ±0.025 mm — on every feature, including cosmetic areas.

The Problem:

The quote was high, and the estimated lead time exceeded the client’s production schedule.

The Solution:

Our engineers reviewed the design and proposed a simple but effective adjustment: maintain ±0.025 mm only for functional interfaces and relax non-critical areas to ±0.1 mm.

The Result:

- Cost reduced by 30%.

- Lead time shortened by five days.

- Functionality unaffected.

Partnering with an experienced China CNC machining service like JS Precision provides access to this expert guidance, ensuring your designs are not only precise but also optimized for manufacturability and cost.

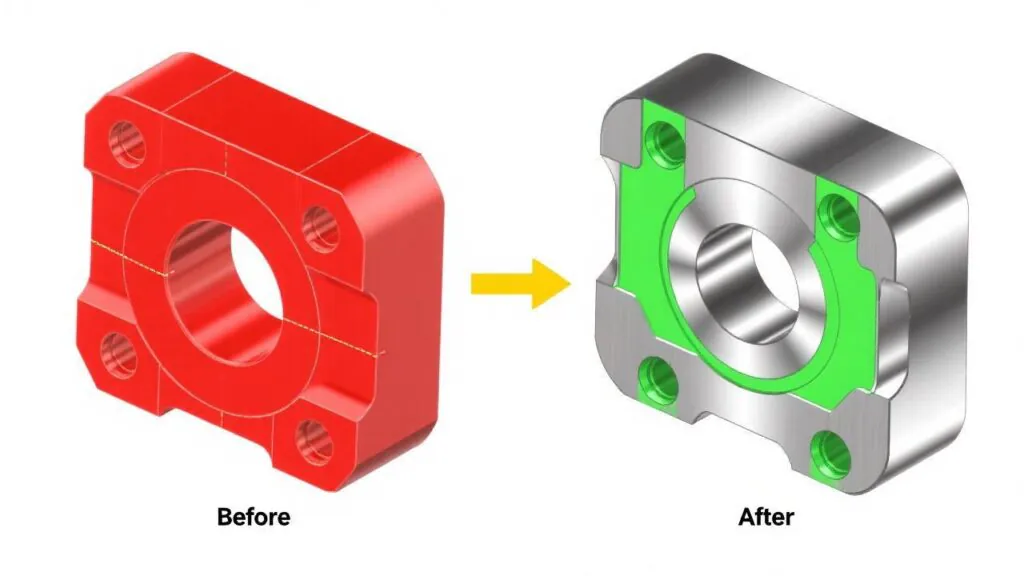

Figure 3: A visual DFM optimization comparison. (Left) Initial design: Tight tolerances on all features drove up cost. (Right) Optimized by JS Precision: Tight tolerances applied only to critical functional areas, reducing cost significantly.

Conclusion: Precision Meets Practicality

Practicality and precision should be hand in hand in CNC machining. Strict tolerances will soon increase costs, delay production, and make inspection difficult, yet without any benefit to the end product.

With the careful application of tolerances, designers can achieve performance and control CNC machining cost and lead time.

Ready to Optimize Your Designs and Costs? When you have a new design or CNC prototyping, the engineering team at JS Precision is ready to assist you. The company provides free DFM analysis and instant quotes to help you make informed decisions about tolerances, ensuring you get the highest quality parts at the most competitive price and lead time.

-

Resources4 years ago

Resources4 years agoWhy Companies Must Adopt Digital Documents

-

Resources3 years ago

Resources3 years agoA Guide to Pickleball: The Latest, Greatest Sport You Might Not Know, But Should!

-

Resources7 months ago

Resources7 months ago50 Best AI Free Tools in 2025 (Tried & Tested)

-

Guides1 year ago

Guides1 year agoGuest Posts: Everything You Should Know About Publishing It