Resources

Why Scalable Physical Infrastructure Still Matters in the Age of Digital Startups

In the modern startup landscape, scaling discussions often focus on digital tools. Founders talk about automation, data analytics, customer relationship software, and artificial intelligence, and they believe that these alone will secure growth. These elements are important, but they risk overshadowing the equally vital role of physical infrastructure.

Early-stage companies often pour resources into digital systems because they offer measurable results and quick feedback. Physical operations, by contrast, are sometimes seen as background tasks to be dealt with later. For product-based startups, this thinking can create serious bottlenecks.

Physical infrastructure is not simply a support function. It is a foundation for delivering orders accurately, on time and at scale. Without it, the most advanced forecasting software or marketing automation will not prevent operational delays and customer dissatisfaction.

For physical product startups, infrastructure matters as much as marketing, and scale begins with what is on your floor, not just what is in the cloud. This is not an abstract concept; it is a practical truth that can define the trajectory of a scaling business.

The ability to expand without disruption depends on having systems that can handle both routine demand and unexpected spikes. That applies to eCommerce brands, light manufacturers and B2B wholesalers alike.

Scaling a company that works with physical goods means understanding that space, movement, and standardisation are just as critical as any digital metric. The physical and digital must evolve together, not in isolation.

Reusability and Modularity = Scalability

Infrastructure does not need to be static. In fact, the most effective systems are modular and reusable. This flexibility allows businesses to adapt to new product lines, seasonal peaks or changing client demands without extensive reconfiguration.

Reusable containers, stackable bins and standardised pallets offer clear advantages. They can be used in storage, during handling and in transport, reducing the need for multiple equipment types. When designed to industry standards, they can also integrate with automated systems introduced later in the growth cycle.

Working with a UK-based professional logistics supplier ensures that scaling businesses gain access to equipment that supports long-term efficiency. Suppliers like Alison Handling help bridge the operational gap with reusable, modular systems that support long-term growth, proving that operational design is as critical to scale as product innovation.

The goal is not to buy in bulk but to invest in systems that are consistent, compatible and easy to reconfigure. This approach avoids the trap of piecemeal investment. Without standardisation, businesses can end up with a mix of incompatible equipment, leading to wasted space and inefficient processes.

The operational benefits of modular systems are significant. They reduce downtime when workflows change, simplify procurement and improve handling safety. This makes them especially valuable in facilities where space is limited and adaptability is critical.

For a growing business, adaptability is often the deciding factor in whether seasonal peaks are managed smoothly or cause costly disruption. Modular infrastructure makes that adaptability possible.

In the scaling phase, the ability to adjust quickly without major investment is a competitive advantage that should not be underestimated.

Physical infrastructure also protects brand reputation. In markets where late delivery or damaged goods can end client relationships, operational stability is as valuable as marketing reach.

In the long term, a strong physical foundation will support every other aspect of the business, from customer service to investor confidence.

The Blind Spot in Startup Scaling

In many scaling strategies, physical infrastructure receives less attention than digital systems. Product roadmaps may focus on software features, marketing funnels and user experience design while leaving operational planning to a later stage. This can lead to costly problems when growth accelerates.

Investor conversations frequently focus on customer acquisition, churn rates and digital conversion metrics. While these are important, they do not reflect the operational realities of fulfilling physical orders. When those realities are ignored, they can become a major barrier to scaling.

A common issue occurs when a company excels at generating demand but struggles to fulfil it. Without the right equipment, processes and space, fulfilment teams may face delays, product damage and higher labour costs.

Over time, these issues erode profit margins and damage customer trust, and insights from Amazon on why bad delivery experience damages customer loyalty show that late or incorrect orders can have a greater impact on retention than many other service problems.

Early-stage teams often rely on improvised facilities. Storage areas might be cramped, handling systems may be mismatched, and workflows might have evolved without structure. These arrangements can work for small volumes, but they are rarely fit for rapid growth.

The startup culture of rapid adaptation can make this worse. In software, fixing issues is often a matter of deploying an update. In physical operations, correcting a poorly designed layout or replacing unsuitable equipment is a more disruptive and expensive process.

Founders can underestimate the link between operational capacity and customer retention. Securing new orders is only beneficial if those orders are processed and delivered efficiently.

Operational readiness should be part of the scaling conversation from the outset. Businesses that prepare their physical infrastructure early are less likely to face crises when demand spikes.

The Sustainability Factor

Scalable infrastructure also supports sustainability goals. Reusable containers and long-life pallets reduce reliance on single-use packaging, cutting costs and environmental impact at the same time.

Better use of space through modular logistics can lower the footprint of storage facilities. Smaller facilities use less energy for heating, cooling and lighting, which reduces both environmental impact and operational costs. Optimised layouts also improve workflow, which means less time and energy is spent moving goods unnecessarily within a facility.

For companies in regulated industries, durable equipment offers compliance advantages. Hygiene-sensitive sectors benefit from materials that are easy to clean and maintain, which reduces waste from damaged or unsuitable items.

Hygiene-critical operations, in particular, can benefit from the durability and design of plastic pallets. Their long lifespan reduces replacement cycles, and their standard dimensions improve stacking efficiency, which helps with both operational planning and environmental reporting. Their adaptability means they can be reused across different product lines, further reducing procurement needs.

Sustainability is also a matter of market perception. Customers, partners and investors increasingly expect businesses to demonstrate their environmental responsibility. Showing tangible operational changes, such as reduced waste or energy consumption, can help a business meet ESG reporting requirements and improve its standing in tenders or supplier evaluations.

Suppliers that offer reusable and modular systems enable businesses to meet these expectations while strengthening operational capacity. This combination of environmental and efficiency gains makes scalable infrastructure a strategic decision, not just an operational one.

Long-term thinking in infrastructure planning positions companies as responsible industry players while reducing the risk of future regulatory penalties. Forward-looking decisions on equipment and layout now will continue to deliver value for years to come.

Why Physical Infrastructure Still Matters

Any company that makes, stores or distributes physical goods depends on the smooth flow of materials. Infrastructure enables that flow and keeps it consistent, safe and cost-effective. Ignoring it during growth introduces unnecessary friction into every stage of operations.

Core elements include storage systems that can adapt to volume changes, equipment that ensures safe handling and layouts that optimise available space. These are not simply warehouse concerns; they are strategic decisions that shape how efficiently a business can respond to market shifts.

Small operations can get by with flexible, improvised setups for a while. Shelving can be reconfigured and boxes stacked creatively, with processes adapting in real time. Yet as orders grow, these quick fixes often turn into inefficiencies.

When the right infrastructure is in place, it reduces downtime, lowers operational costs and allows the business to absorb fluctuations in demand without disruption. This is particularly valuable for seasonal industries and for companies experiencing rapid customer acquisition.

Overbuilding infrastructure from the start can tie up unnecessary capital. The better approach is to invest in systems that can expand and adapt as the business grows. These systems should support both present-day needs and foreseeable changes in volume, product type and fulfilment requirements.

In the UK, sectors from pharmaceuticals in the North West to chilled food production in the Midlands have shown how modular systems and reusable containers can handle seasonal peaks without expanding site footprints.

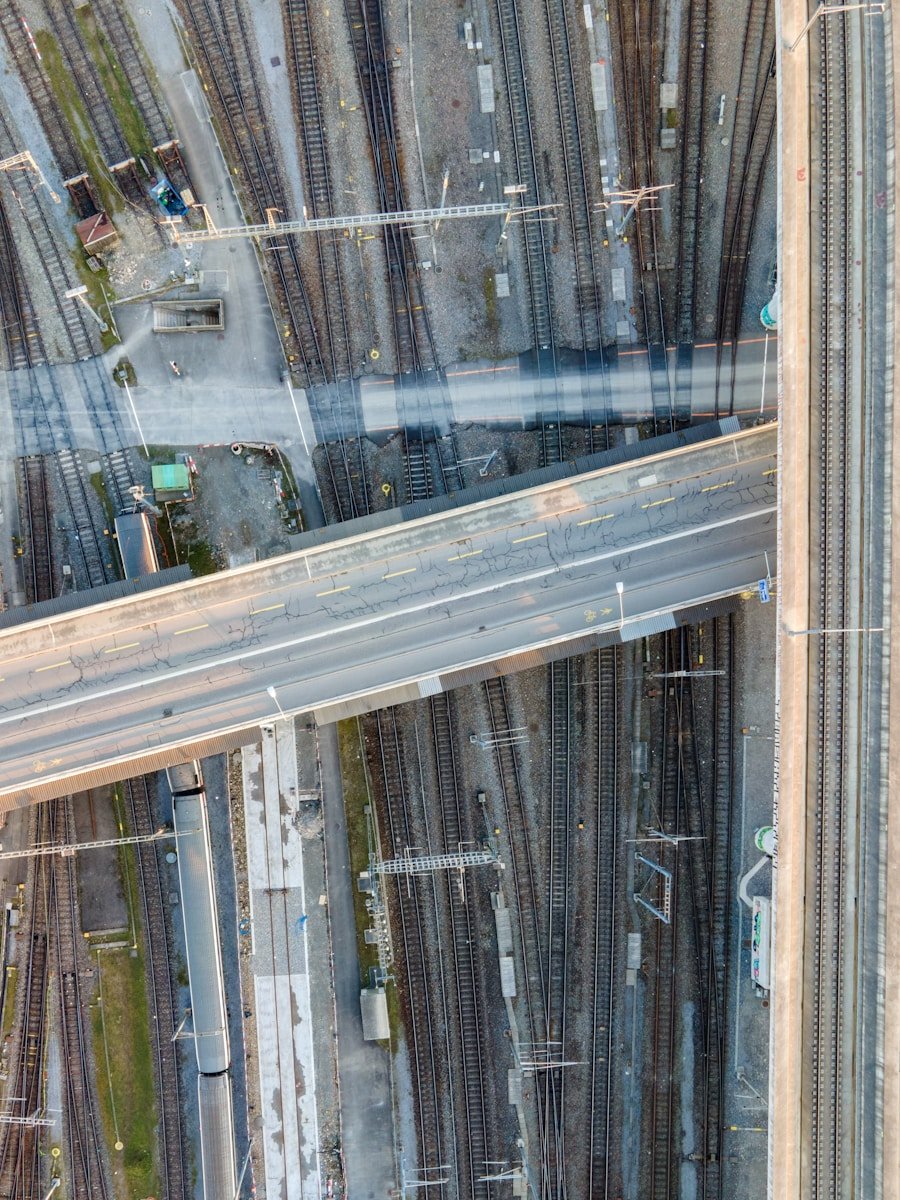

Regional hubs, such as those around the M62 corridor, often rely on scalable infrastructure to move goods efficiently between manufacturing plants, warehouses and final delivery points.

From Chaos to Control: The Role of Smart Container Systems

The standardisation of handling equipment is one of the most effective ways to prepare for growth. Systems such as modular pallets and containers are more than storage tools; they shape how goods flow through the supply chain.

Standard sizes make it easier to design warehouse layouts, optimise transport loads and work with external logistics providers. They also reduce the risk of mismatched equipment causing bottlenecks.

Even minor inefficiencies can become costly at scale. A container that wastes a small amount of space on each shelf may seem harmless, but across hundreds of units that loss compounds into reduced capacity and higher costs.

Plastic-based systems offer further benefits. They are more durable than wood, easier to clean and resistant to moisture. For sectors with hygiene regulations, this resilience is crucial for compliance and for reducing replacement costs.

Integrating standardised, reusable equipment early creates a predictable operational rhythm. Goods can be received, processed and dispatched without unnecessary repacking or adjustments.

This is the physical equivalent of process automation in software. It replaces improvised, manual work with a consistent, efficient sequence that can be scaled without loss of quality.

By committing to standardised systems, businesses build a stable foundation for growth that is less vulnerable to operational shocks.

Why Founders Should Not Ignore This

Physical infrastructure rarely features in headlines about innovation. It may not attract attention in the same way as a new product launch or a funding round, yet it is the foundation on which all growth depends for any business that handles physical goods.

Neglecting infrastructure creates vulnerabilities. A sudden spike in demand, a shift in product type, or a regulation change can strain unprepared operations.

Businesses that invest early in scalable, modular and reusable systems can respond to change more effectively. They can absorb fluctuations in demand without compromising quality or delivery times.

Founders should see infrastructure as an enabler rather than a cost. It influences daily operations, affects customer satisfaction and determines how smoothly a company can expand.

Operational resilience is a key advantage in the competitive landscape of physical product businesses. Infrastructure planning is not optional; it is essential.

Scaling without chaos comes from deliberate investment in infrastructure, not luck. For product-based businesses, that investment can be the difference between becoming a lasting success or a cautionary tale.

-

Resources4 years ago

Resources4 years agoWhy Companies Must Adopt Digital Documents

-

Resources3 years ago

Resources3 years agoA Guide to Pickleball: The Latest, Greatest Sport You Might Not Know, But Should!

-

Resources8 months ago

Resources8 months ago50 Best AI Free Tools in 2025 (Tried & Tested)

-

Guides2 years ago

Guides2 years agoGuest Posts: Everything You Should Know About Publishing It